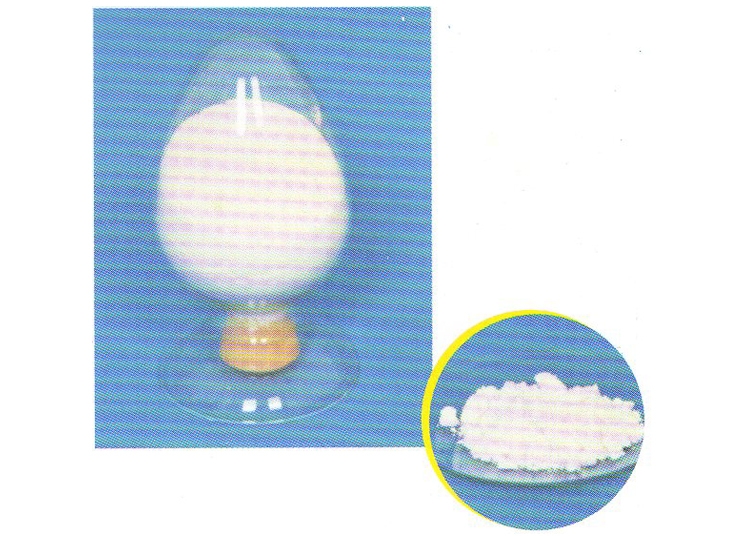

During the production of magnesium sulfate monohydrate, everyone is concerned about its purity. Generally, to produce chemical products with better purity, some professional operation methods should be adopted. The impact of purity is often caused by foreign invading impurities, so what you need to do is to purify and remove impurities. Here's how to teach you. Magnesium sulfate monohydrate

1. First of all, we should improve the purity of magnesium sulfate monohydrate raw materials, and purchase or make high-purity raw materials. If the purity of raw materials is not high or even contains impurities, it can be imagined that the quality of finished products will not be high.

2. Secondly, do not mix other substances, including gas, in the reaction process to prevent the gas from oxidizing the substances in the reaction process or even causing other reactions.

3. The other is to filter and purify as needed after reaction. Take magnesium sulfate monohydrate as an example, add it into a hot distillation tank containing 80 ℃~90 ℃, heat it while stirring, dissolve it to a mass concentration of 1.21g/cm3, remove impurities such as arsenic and heavy metals with alkali, decolorize it with activated carbon after filtering, concentrate it to a mass concentration of 1.370g/cm3~1.384g/cm3, cool it, crystallize it, separate and wash it when the temperature reaches 25 ℃~15 ℃, dry it in a vibrating fluidized bed at 50 ℃~55 ℃, depending on the water quality, impurity removal, decolorization and washing degree, Get different grades.